ClimateCore-A

Patent Pending

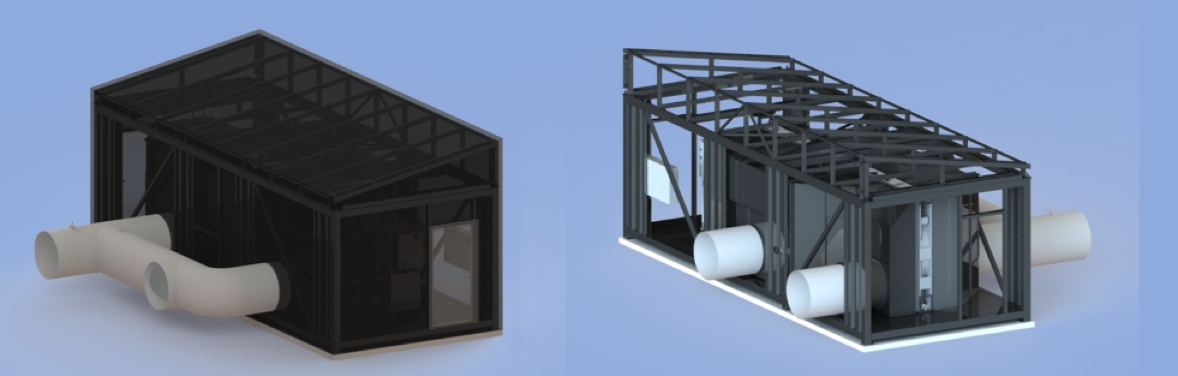

Product description

- The main purpose of the product is to reduce the overall energy costs for greenhouse owners and increase the yield by improving the climate and reducing the need for venting out humidity and by that also CO2.

- The product dehumidifies the greenhouse air to required humidity and temperature levels by two different technologies. The greenhouse air is circulated through a setup of heat exchangers and is returned to the greenhouse and thus keeps the CO2 inside the greenhouse.

- In situations with excess energy in the recirculated greenhouse air the product additionally collects the energy using a heat pump. This hot water can be stored for later use.

- It can be used for cooling, then the excess energy will be stored for later use. Optionally there can also be a functionality and equipment for humidification, if so required.

Technical specification

- The dehumidification performace is between 200-500 kg water per hour depending on ambient and greenhouse air properties.

- The heat recovery function can recover 100kW of useful heat.

- The energy reduction compared to traditional ventilation will be approximately 85% lower and the calculated total energy reduction on a yearly basis is in the interval 40-60% depending on project.

- One standard sized module is designed for approximately one hectare of greenhouse, the module is prefabricated by a partner manufacturer with extensive manufacturing experience for the industry.

- Fulfills all the required EN standards to comply with Machinery Directive 2006/42/EC

Project delivery

- The product is highly standardized for cost, quality, and delivery reasons.

- The integration to the customer is a project specific design where high flexibility is possible both on the mechanical and automation side.

- The product has an own HMI but should be integrated to the greenhouse climate computer for seamless integration into the climate control strategy of the specific grower.

Flue gas condensers

- Typical installation reduces fuel consumption for bio fuelled boiler with 10-25% depending on fuel moisture content and district heat return water temperature and dependent on scrubber design if it is with or without combustion air pre-heating

- Project specific design , get in contact for questions and answers!

Special products

- What you dream of we might be able to assist on…